Lot sampling inspection plan

- The inspection can only start when the entire batch of goods has been completely 100% finished and packed into the outer box.

- Check the quantity carefully before sampling the carton box, and randomize when checking the outer box. Ensure that the number of spot checks is accurate and reasonable. The number of samples in the outer box is: the total box number is squared and then plus1.

- Before the visual inspection, check the packaging of the products selected for inspection.

- Make sure that the samples taken are evenly distributed in each of the carton boxes.

- General appearance inspection level: Level-II; special function inspection level: S-3

Acceptance Quality Limit (AQL)

critical = 0

major = 1.0

minor = 2.5

(AQL is usually set to 0 / 1.0 / 2.5, but customers can define it themselves.)

If one of Critical Issue, Major Issue, or Minor Issue is out of acceptance, the batch will be REJECT.

- After the inspection, the inspector must check the quality problems found in the inspection with the factory quality management person, and record the inspection result in the Inspection Report.

Definition of Defect Levels

-

Critical Issue (Fatal Defect):

1.1 Involving safety or violating laws and regulations, such as high voltage leakage test failure, battery leakage, or products with sharp points, sharp edges, smoke, fire, or small items that are easily swallowed by toys (such as toys or products) A certain part, small objects that fall off or form after a drop test), or there are extra sharp objects (such as blades, scissors, sewing needles, etc.) in the package, or other defects that do not meet safety requirements.

1.2 If it is found that the brand name or logo on the label or tag is wrongly used as another trademark or logo.

1.3 Safety warning labels / tags are missing from the product.

1.4 There are hair, insects and blood stains in the package or on the product. Wrong product or wrong materials in packaging.

1.5 The battery can still be turned on when it is reverse loaded

1.6 The packaging does not match the information or the packaging contains the wrong product or the wrong materials are used.

1.7 The product or packaging has an irritating odor (unless otherwise specified by the guest)

1.8 There are obvious water drops on the package or product, or mold and rust

1.9 Other items specified by the customer

-

Major Issue (Main Defect):

Defects that will affect the sales of the product, rather than fatal functional or appearance defects: if the light is off, the ultrasound is poor, missing parts or components, cannot be sensed, the switch is not working, the function is incomplete, severe soiling / oily soil / clothing Wait.

-

Minor Issue (Minor Defect):

Defects that do not significantly reduce the expected performance of the product or deviate from the standard but only slightly affect the effective use or operation of the product. Such as: slight scratches, easy-to-remove stains, shrinkage that affects appearance but can remove defects, and does not affect function.

dirty on surface — minor issue

General inspection items

-

Packaging

1.1 According to the requirements of customers, product packaging must be neat and clean, no broken materials, no pollution, and it has a real protective effect on the product

Inspection equipment: visual inspection

1.2 The product packaging is an important part of the product. The inspector needs to check the product quantity, brand, color, packaging method, mix and so on according to the information.

Inspection equipment: visual inspection

1.3 Metal nails are not allowed on all outer boxes & gift boxes, unless the customer confirms by mail (except domestic turnover boxes)

Inspection equipment: visual inspection

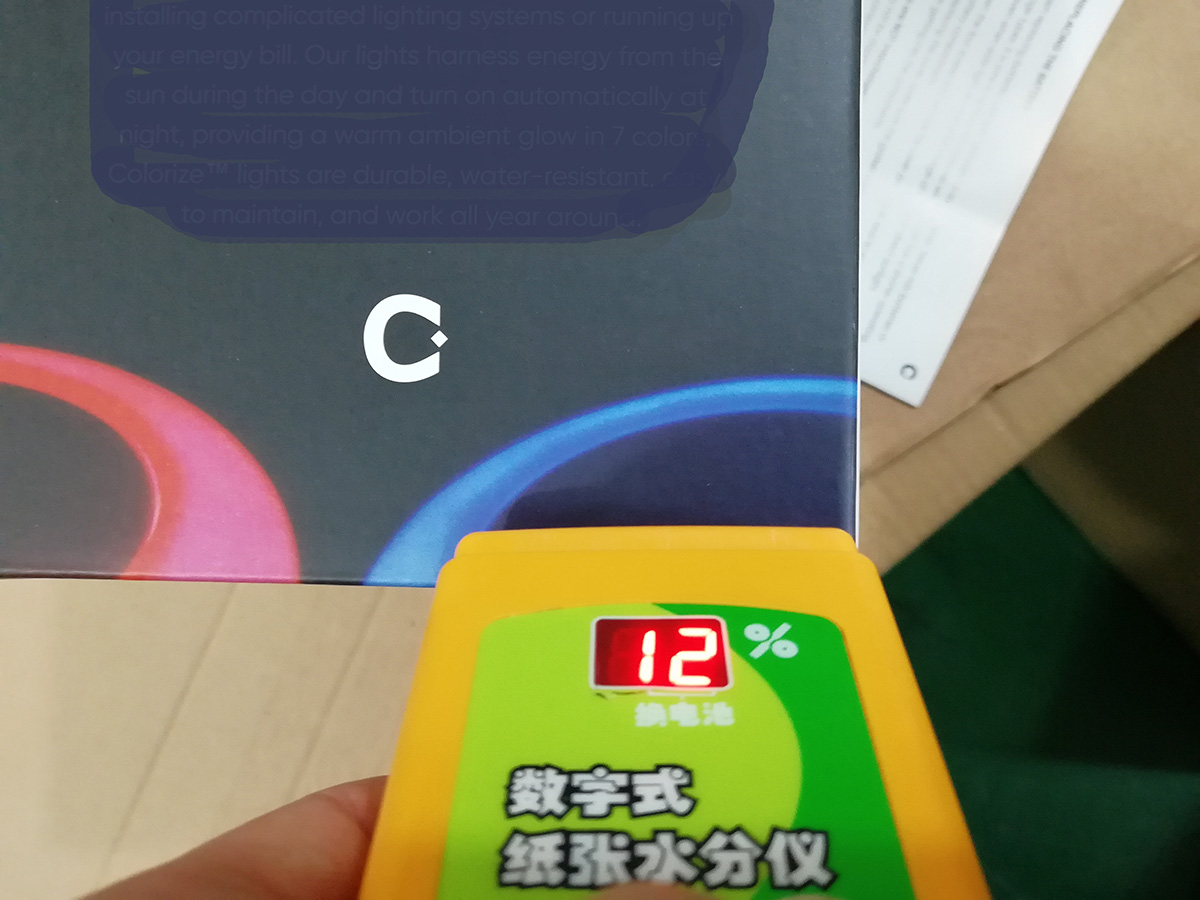

1.4 Carton & Color Box Moisture Test

Inspection standards and inspection contents: Carton moisture content range 8% -12%

Inspection equipment: hygrometer

carton box moisture test

color box moisture test

1.5 Check whether the weight and size printed on the box are consistent with the actual (tolerance ± 5%)

Inspection equipment: electronic scales and tape measures

1.6 Check whether the color, size and printing of the color box are correct, whether the UPC code is correct and scannable.

Inspection equipment: visual inspection & barcode scanner

1.7 Carton Drop Test

Inspection standards and inspection methods: whether the carton can withstand transportation. Drop box height: The outer box must be determined according to the actual gross weight (see the table below), and the height is measured from the lowest point of the outer box.

| Gross Weight | Height | ||

| (LBS) | (KGS) | (INCH) | (CM) |

| 0≤GW<21 | 0≤GW<9.5 | 30 | 76.2 |

| 21≤GW<41 | 9.5≤GW<18.6 | 24 | 61.0 |

| 41≤GW<61 | 18.6≤GW<27.7 | 18 | 45.7 |

| 61≤GW<100 | 27.7≤GW<45.3 | 12 | 30.5 |

| 100≤GW<150 | 45.3≤GW<68 | 8 | 20.3 |

The drop test shall be in the order of one corner, three sides and six sides.

Weakest angle (two corners where the seam edge is)

Near the shortest side with the weakest angle

Approaching the weakest angle Next longest side

The longest side near the weakest angle

Smallest plane

Opposite the smallest plane

Midplane

Opposite Midplane

Largest plane

Inspection equipment: manual or carton drop machine

For detail Inspection Procedure of Carton Drop Test, please refer to another article below: https://wayinspection.com/packaging-drop-test-during-pre-shipment-inspection/

1.8 Check after drop test:

If the carton breaks or cracks, the drop test fails;

If the packaging of the product at the corner where it was dropped is broken, but the product itself functions normally, the drop test passes;

If the product packaging materials in other locations are damaged, the drop test fails;

If any product in the box loses function or functions abnormally, the drop test fails;

Inspection equipment: manual, visual inspection

-

Product appearance

2.1 Product shape & color

Inspection standards and check points: Refer to the customer’s sample, the product must be within the upper and lower limits.

Inspection equipment: visual inspection

2.2 Product appearance

Inspection standards and check points: color difference, sharp edges, scratches, dirt, top white, mold marks, poor logo printing, slippery or missing screws, rusty metal parts, manual printing, etc., refer to limit samples in special cases

Inspection equipment: visual inspection

2.3 Solar panel inspection

Inspection standards and check points: Is the solar panel a single crystal panel (no pattern, dark blue, almost black after packaging) or a polycrystalline panel (patterned, polycrystalline colorful and polycrystalline less colorful, like snowflakes on a snow sheet) Crystal pattern, light blue), refer to the sample

Inspection equipment: visual inspection

-

Product Features

3.1 Switch button

Inspection standards and inspection methods: press the switch button, the white light is on; press again, the red light is on; press again, the green light is on; press again, the blue light is on; press again, the change light is on; press again Once, the light went out.

Inspection equipment: visual inspection

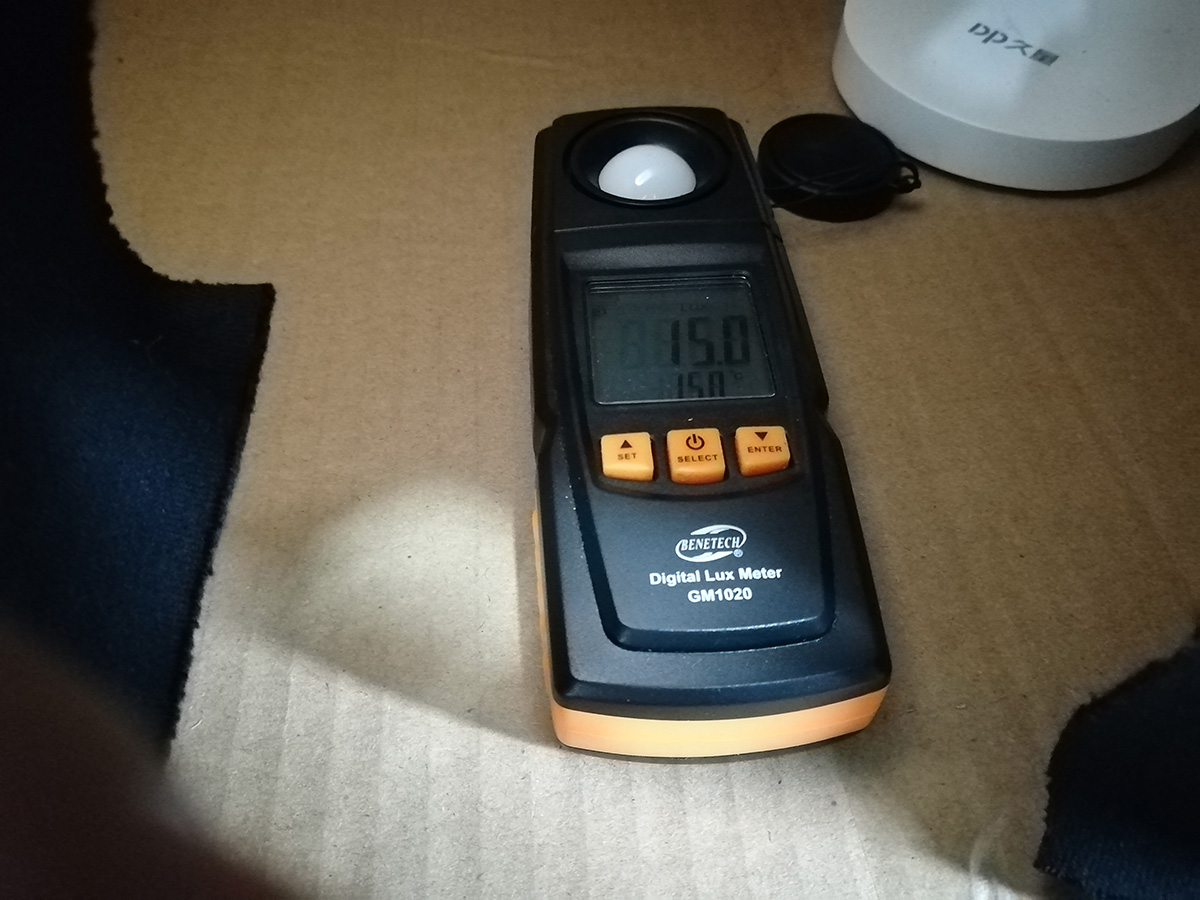

3.2 Photosensitive switch function

Inspection standards and inspection methods: Turn on the switch, place the product in a dark box with a brightness of not less than 15LUX, and the light is on; place the product in an environment with a brightness of 150-200LUX, and the light is off.

Inspection equipment: dark box & digital lux meter

auto on / off test

digital lux meter

Special Inspection Items

-

Solar panel open circuit voltage check

Inspection method: Use a 500W halogen lamp, the light intensity is set to 3.8 ~ 40000 LUX, the distance between the lamp and the test platform is about 15-20CM, the solar panel is placed on the platform, and the voltage is tested with a multimeter

Quality standard: the voltage should be within the rated voltage range

Inspection equipment: halogen lamp & multimeter

solar panel voltage test

-

Solar panel short-circuit current check

Inspection method: Use a 500W halogen lamp, the light intensity is set to 3.8 ~ 40000 LUX, the distance between the lamp and the test platform is about 15-20CM, the solar panel is placed on the platform, and the current is tested with a multimeter

Quality standard: the current should be within the rated current range

Inspection equipment: halogen lamp & multimeter

-

Solar panel working current check

Inspection method: Use a 500W halogen lamp, the light intensity is set to 3.8 ~ 40000 LUX, the distance between the lamp and the test platform is about 15-20CM, the solar panel is placed on the platform, and the positive and negative electrodes are connected in parallel with a corresponding resistance (Calculation of resistance value: R = U / I), test its working voltage with a multimeter

Quality standard: the current should be within the rated current range

Inspection equipment: halogen lamp & multimeter & resistance

-

Solar panel working current check

Inspection method: Use a 500W halogen lamp, the light intensity is set to 3.8 ~ 40000 LUX, the distance between the lamp and the test platform is about 15-20CM, the solar panel is placed on the platform, and a corresponding resistance (resistance value) is connected in series Calculation: R = U / I), test its working current with a multimeter

Quality standard: the current should be within the rated current range

Inspection equipment: halogen lamp & multimeter & resistance

-

Assembly test

Inspection method: the bracket can be assembled on the lamp

Quality standard: can be assembled smoothly, without jamming and assembly failure

Inspection equipment: manual & visual inspection

-

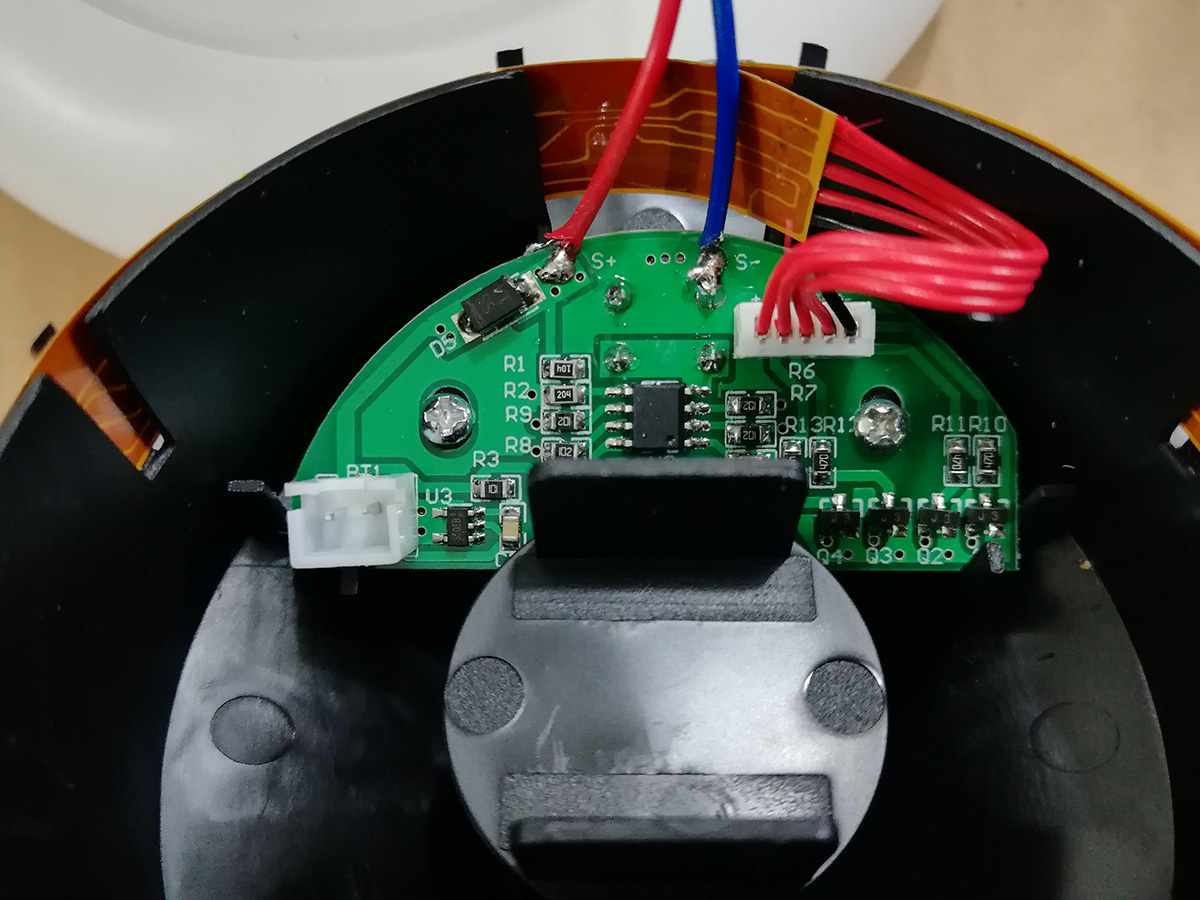

Disassembly inspection

Inspection method: open the shell of the lamp, check whether the internal wiring is clear and reasonable, and the component model is correct

Quality standard: the reference sample which customer signed for pre-shipment inspection (final inspection). the internal wiring is clear and correct, and the component model is correct

Inspection equipment: screwdriver & visual inspection

disassembly inspection

-

Constant light test

Inspection method: leave the lamp on for 8 hours

Quality standards: the lights are not turned off, and there is no obvious dimming of the lights

Inspection equipment: visual inspection

lighting time run-in test

-

Switch life test

Inspection method: Simulate the use of pressing the switch button, press 100 times in a row

Quality standard: After testing, the switch function is normal and the product function is normal

Inspection equipment: manual & visual inspection

-

Waterproof test

Inspection method: Put the product under the spray equipment, the height is 2-2.5m, and the spray time is at least 5 minutes

Quality standard: The product is functioning normally and there is no water in it

Inspection equipment: spray equipment

waterproof test

-

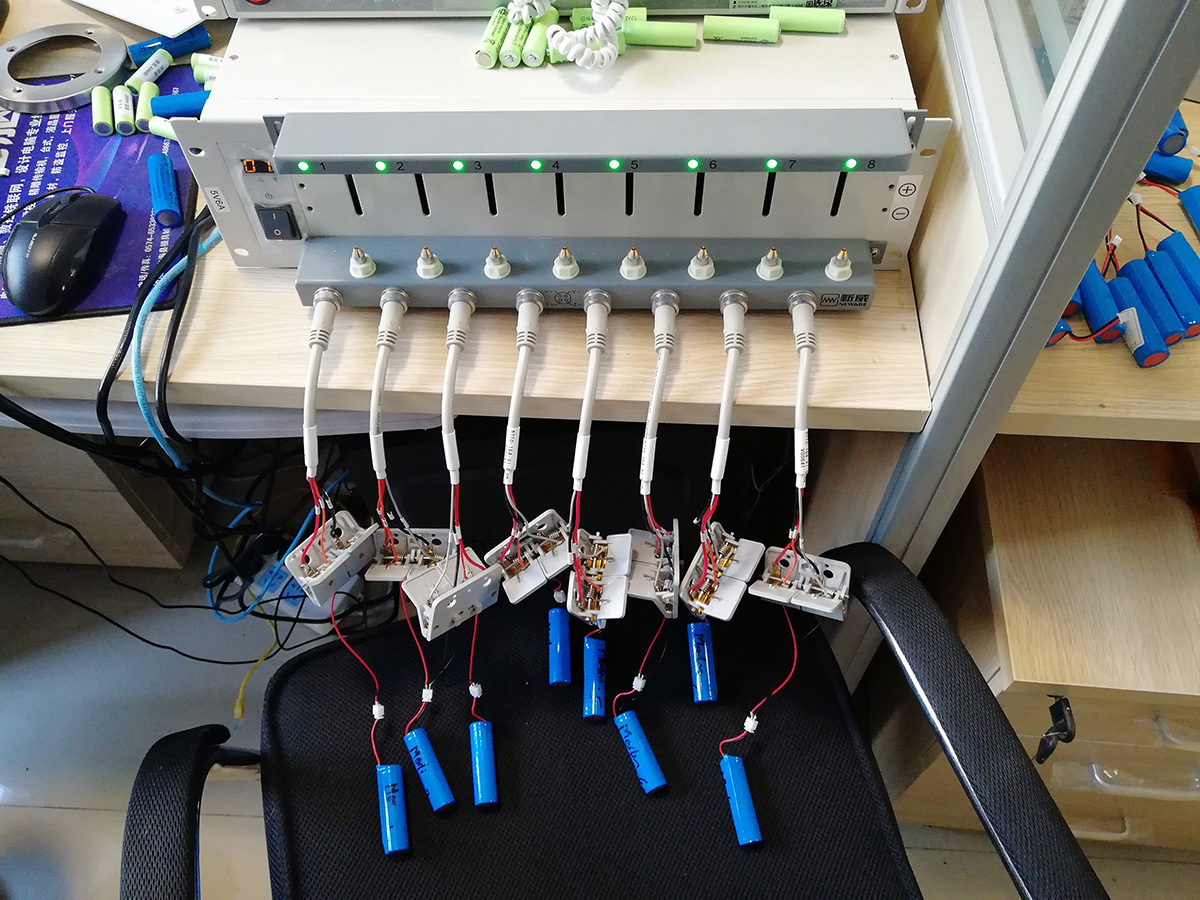

Battery capacity check

Inspection method: Place the battery on the battery capacity tester, and read the value after at least two cycles of charging and discharging.

Quality standard: the capacity should be within the rated range

Inspection equipment: battery capacity tester

battery capacity test

-

Battery voltage test

Inspection method: use a multimeter to measure the battery voltage

Quality standard: the voltage should be within the rated voltage range

Inspection equipment: multimeter