Many customers consult the inspection process of our vacuum insulated stainless steel water bottles. Many of them use our quality inspection services every month. China has become a major producer and exporter of stainless steel insulated bottles worldwide. China factories export a large number of incubators to the world every year. WayInspection team has extensive experience in inspecting insulated stainless steel bottles. Here, we will share the Specific Inspection Criteria of vacuum insulated stainless steel water bottles.

Sampling inspection plan

General inspection level (appearance): General-II

Special inspection level (functionality): S-3

Acceptable quality level (AQL):

Critical issue = 0

Major issue = 1.0

Minor issue = 2.5

If one of Critical issue, Major issue or Minor issue is out of range, the batch will be REJECT.

Defect level definition

1. Critical issue (fatal defect)

Defects that damage the important, final, basic functions of the product, and the potential for harm to the health of the consumer or the body. This includes all the shortcomings that make the part unusable and the assembly or appearance defects cause the customer to refuse to use. Such as: lack of insulation efficiency, water leakage due to structural defects, sharp mouth water, and material hygiene indicators are not up to standard. Critical issue (fatal defect) is represented by A.

2. Major issue (main defect)

Defects that can cause failure or significantly reduce the expected performance of the product. Such as: size does not match, severe deformation, serious trauma, color error, LOGO ink adhesion, paint, severe white, large color points. Major issue (main defect) is represented by B:

3. Minor issue (minor defect)

Defects that do not significantly reduce the expected performance of the product, or defects that deviate from the standard but only slightly affect the effective use or operation of the product. Such as: slight scratches, easy to remove stains, affect the appearance but can remove defects, does not affect the function of shrinkage, coating color cast. Minor issue (minor defect) is represented by C.

General Inspection Check Points

| Check Points | Inspection Criteria and Inspection Content | Inspection Criteria | Inspection Equipment | Defect Grade |

| Coating | Color | Comparing with reference sample. Should be within the upper and the lower limits | Visual Inspection | B |

| Appearance | Scratches, impurities, pinholes, exposed bottom, dirt, etc., are not allowed. For special issue not listed above, should refer to limit samples | Visual Inspection | B, C | |

| Printing | Color | Comparing with reference sample. Should be within the upper and the lower limits | Visual Inspection | B |

| Appearance | Stain, dirty, pinholes, leaking bottoms, misalignment, defective printing, blurring are not allowed. | Visual Inspection | C | |

| Wrong print and missing print are not allowed. | Visual Inspection | A | ||

| Stainless Steel part | Dimension | dimension should meet the bottle drawing | Caliper, Height ruler | B |

| Appearance | Scratches, dents should refer to limit samples | Visual inspection | C | |

| No dirt, hair, stain and leftovers inside | Visual inspection | C | ||

| Packaging | Printing | The printed contents of the carton, the manual, the price tag, etc. are consistent with the reference sample, and there is no printing ghosting, blurring, missing printing, etc. | Visual inspection | B |

| Packing method | The way of placing products and the quantity of packaging meets the requirements of the packing process, and there is no upside down, disorder, product exposure, etc. | Visual inspection | B | |

| Labelling | Content | Labels on products, gift boxes and carton boxes should be same as customer requires. Barcode should be scannable. | Visual inspection and Scanner | B |

| Printing | Should be clear. No Blurring, no missing printing. | Visual inspection | B |

Typical cosmetic issue

Special Test Check Points

Check point 1: Capacity

Inspection Equipment: Electronic scale

Inspection Method:

Normal temperature water weighing measurement method: the weight after filling with water and sealing the weight minus the weight of the empty bottle, measured according to the standard of 1g = 1ml;

Container capacity measurement method: fill the water and seal the cover and remove the seal Cover, pour water into the measuring container, and read the value in the container as the capacity value.

Quality Performance / Inspection Criteria:

When performing the above test, the identification capacity should be within ±5% deviation of the measured capacity.

Check point 2: Insulation Performance

Inspection Equipment: Thermometer

Inspection Method:

Different bottles with different shape, lid type, mouth diameter, capacity should have different insulation testing criteria.

To make it clear, for example, we take Hydro Flask (Simple Modern, Takeya or Hydro Cell) wide mouth water bottle 32 oz. Put the bottle at the room of temperature (20 °C ± 5 °C) for more than 30 min to ensure the bottle temperature is same as the room temperature.Pour the boiling water into bottle and fill the bottle till reach the lower end of the sealing cap (lid). When the measured temperature in the bottle reaches 95 °C ± 1 °C, immediately tighten the cap. Under the same environmental conditions, after 24 hours, determine the water temperature inside the insulated bottle, which should be higher than 44 ° C

Quality Performance / Inspection Criteria:

Different bottles with different shape, lid type, mouth diameter, capacity should have different insulation testing criteria.

Check point 3: Sealing Performance

Inspection Equipment: Room Temperature Water

Inspection Method:

Fill the bottle with warm water. After screwing in the cap, keep the bottle upward and swung the bottle. the frequency is 1 time/S, 500mm, and it is swung up and down 10 times. After being placed in the following state, check whether there is water leakage; (1) mouth downward 30 minutes (the cap is not in contact with the desktop) (2) Horizontal position for 30 minutes

Quality Performance / Inspection Criteria:

When carrying out the above tests, the bottle should leak out without water.

Check point 4: Torque test for bottle cap

Inspection Equipment: Torque meter

Inspection Method:

Fill the water bottle with a full amount of boiling water, then hand-tighten the water lid (cap), and use 3N.M torque to rotate in the direction of tightening.

Quality Performance / Inspection Criteria:

When the above test is carried out, the lid (cap) does not slip.

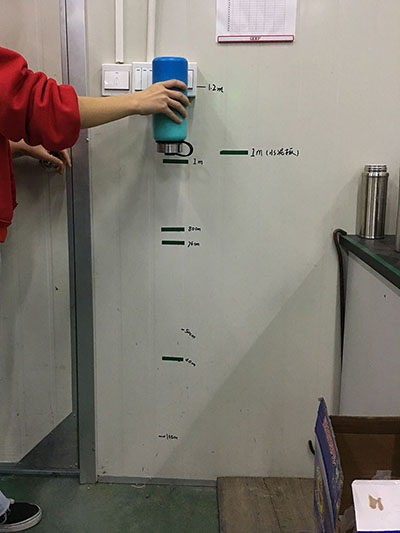

Check point 5: Bare drop test

Inspection Equipment: Drop test equipment

Inspection Method:

Fill the product with a full amount of water, tighten the lid, and under the condition of (1), (2) and (3), let the same water bottle fall naturally;

(1) Place the water bottle straightly at an 100 cm height test bench. Naturally drop;

(2) Place the water bottle horizontally at an 100 cm height test bench. Naturally drop;

(3) Place the water bottle upper side down at an 100 cm height test bench. Naturally drop;

Quality Performance / Inspection Criteria:

When the above test is carried out, the product cannot be obviously deformed / dented nor the function is damaged; the product cannot have the defects of thermal insulation performance and leakage.

Insulated water bottle bare drop test

Check point 6: Silk Screen Printing logo adhesion test

Inspection Equipment: 3M tape

Inspection Method:

After slightly press the position of silk screen printing with a finger with 3M tape, pull it up vertically in the direction of 90°, repeat the above steps 5 times with the newly peeled tape.

Quality Performance / Inspection Criteria:

Perform 3M tape test on printed logos, the imprint should not peel off.

Check point 7: Coating layer adhesion test

Inspection Equipment: 3M tape, knife

Inspection Method:

Cut a 1mm * 1mm grid on the surface of the sample with a hundred-grain knife. The number of horizontal and vertical grids is not less than 10 grids. The scratch depth should be deep and the metal layer. After rubbing off the edges of the grid, press the finger with 3M tape. Flat on the grid, pull up vertically in the direction of 90°, repeat the above steps 5 times with the newly peeled tape

Quality Performance / Inspection Criteria:

The powder coating does not fall off.

Coating layer adhesion test

If you have questions about water bottle quality inspection, please feel free to contact us. We are always here for assist you on quality control and quality inspection.