The packaging drop test (carton box drop test) is an important part of Pre-shipment Inspection. Products that fail packaging drop test during Pre-shipment Inspection will be rejected by inspector.

Let’s Image working with your provider to fabricate a perfect, brilliant item that meets every one of your desires and determinations. Yet, when you get the shipment in your distribution center, you discover the delivery containers have gone to pieces and the merchandise inside are harmed hopeless. The shipment you expected to be beneficial is presently unsellable.

Never expect your supplier will naturally find a way to secure your items with the suitable bundling. When a shipment leaves their office, suppliers believe they’re never again responsible for any issues that emerge amid transportation and taking care of.

Testing purposes

This test is usually used to simulate the free fall of the product during handling and transportation and to examine the product’s ability to resist accidental impact. Generally, the drop height is based on the weight of the product and the probability of falling. The drop test impact ground surface should be a smooth, hard, rigid surface made of concrete or steel (if there are special requirements, it should be determined by product specifications or customer test specifications).

Drop Test Method

Preparation of Drop Test

1. The function, safety and appearance of the product shall be tested before the test, and the drop test shall be carried out only after the normal condition is confirmed.

2. The sample must be packed according to the specified method (refer to the production instruction or specification), and the accessories must not be ignored.

3. If the customer has special requirements for sealing (such as belting), it will be carried out according to customer requirements. If the customer has no special requirements, the box is sealed with 2 inch transparent plastic paper, and the outer cartoon box is sealed with 3 inch transparent plastic paper.

4. The test sample should not be less than 2 full boxes or 4 pieces finished products.

Drop Order

The drop methods are one corner, three edges, and six-sided drops. Of course, there are some other standards. There are also provisions for the number of falls and the state of the fall. Here we mainly talk about the conventional test methods of one, three and six sides.

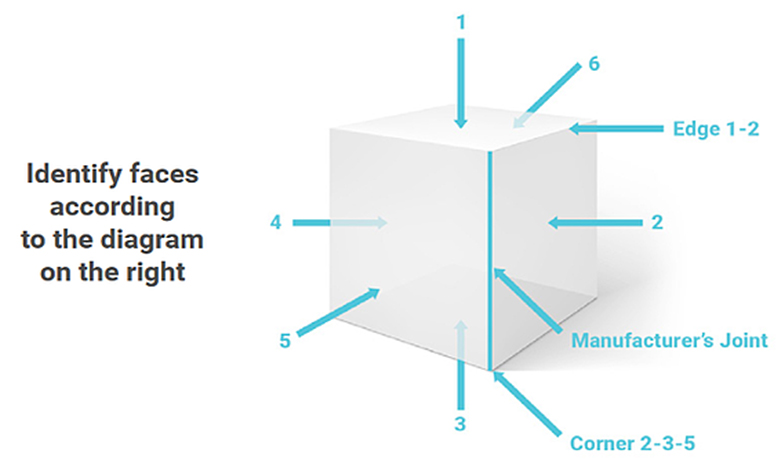

1. To get a sample carton box and firstly we need mark the parts of the sample carton box with numbers.

2. Place the package normally, with one side at the top and three sides at the bottom. These two faces will not change at any time. Then make the smallest face of the carton joint face to yourself, the face is 5 faces, and the opposite face is 6 faces. The larger side of the carton joint is 2 sides, and the opposite side is 4 sides. In this way, a carton box is completely marked. (As shown below)

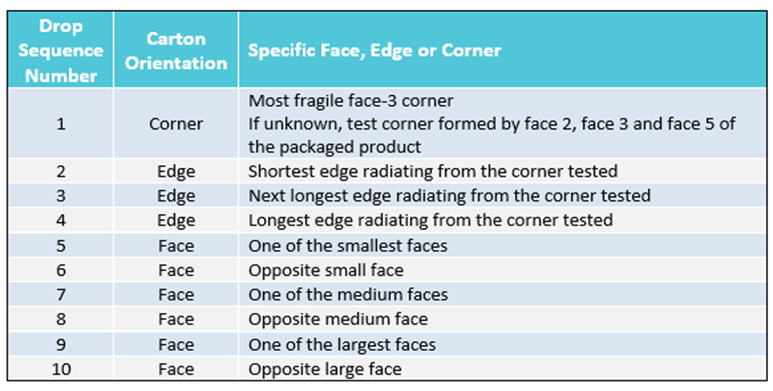

3. Drop the carton from the appropriate height and angle according to the table below. Continue to rotate the carton and drop it from each side following the below sequence, until you’ve dropped the carton a total of 10 times. The order of the fall is:

Angle: 2-3-5;

Side: the shortest side immediately adjacent to the 2-3-5 angle, the longer side, and the longest side;

Face: face 5, face 6, face 2, face 4, face 1, face 3.

Drop requirements

1 The sample is free to fall during the falling process without touching any objects.

2 The impact surface should be a horizontal plane.

Drop height

1. Drop height refers to the vertical distance between the lowest point of the sample and the impact surface after lifting the sample.

2. Drop height according to the sample gross weight refers to the customer test specification standard (if the customer has special requirements) or ISO2248 standard (see the table below):

| Weight | Height | Weight | Height | Weight | Height | ||||||

| kg | Pound | cm | inch | kg | Pound | cm | inch | kg | pound | cm | inch |

| 1 | 2.2 | 100 | 39.00 | 11 | 24.2 | 68 | 26.52 | 21 | 46.2 | 54 | 21.06 |

| 2 | 4.4 | 100 | 39.00 | 12 | 26.4 | 66 | 25.74 | 22 | 48.4 | 53 | 20.67 |

| 3 | 6.6 | 95 | 37.05 | 13 | 28.6 | 65 | 25.35 | 23 | 50.6 | 53 | 20.67 |

| 4 | 8.8 | 90 | 3 0 | 14 | 30.8 | 63 | 24.57 | 24 | 52.8 | 52 | 20.28 |

| 5 | 11.0 | 86 | 33.54 | 15 | 33.0 | 62 | 24.18 | 25 | 55.0 | 52 | 20.28 |

| 6 | 13.2 | 82 | 31.98 | 16 | 35.2 | 59 | 23.01 | 26 | 57.2 | 51 | 19.89 |

| 7 | 15.4 | 79 | 30.81 | 17 | 37.4 | 58 | 22.62 | 27 | 59.4 | 51 | 19.89 |

| 8 | 17.6 | 75 | 29.25 | 18 | 39.6 | 57 | 22.23 | 28 | 61.6 | 50 | 19.50 |

| 9 | 19.8 | 73 | 28.47 | 19 | 41.8 | 56 | 21.84 | 29 | 63.8 | 50 | 19.50 |

| 10 | 22.0 | 70 | 27.30 | 20 | 44.0 | 55 | 21.45 | 30 | 66.0 | 50 | 19.50 |

Inspection / checking after drop test

1. Product performance and safety tests shall be passed.

2. The products should not be crushed, broken and severely deformed.

3. Slight packaging damage and slight appearance changes are acceptable.

If there are major problems (defects) in the test results or if necessary, the inspector will reject the batch of goods. The supplier needs to analyze quality defects of the products and packaging and work out solutions. The drop test should be re-conducted after the issues fixed.

WayInspection is a leading third party quality inspection service company in China. We provide quality inspection service and quality control service such as Pre-shipment Inspection, Initial Production Check, During Production Inspection, Container Loading Inspection, Production Monitoring, Defect Sorting, First Article Inspection, Factory Audit, Social Audit, Business License Check, Laboratory Testing all over China.