What is a Factory Audit?

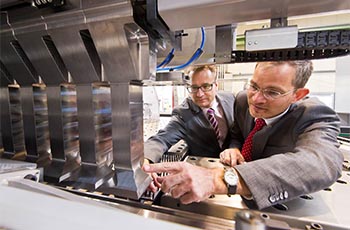

Factory Audits confirm factory ownership, management personnel, legal status, factory size, production capabilities, machinery, materials, packing, quality control, test equipment, certifications.

Your supply chain is only as good as its weakest link. The only way to ensure smooth running of your business and uninterrupted supply of goods is to thoroughly vet potential suppliers before integrating them into your supply chain.

Factory Audits by WayInspection are a cost- and time-effective way to prepare a complete profile of your potential supplier, ensuring they will become a reliable part of your global supply chain. With a WayInspection Audit Report in hand you will be able to confirm that the audited site is capable of delivering to your production specifications, address and prevent potential further costly disruptions once production is launched.

When to Use Factory Audit?

Use this service if you want a truly comprehensive, in-depth appraisal of a prospective or current manufacturer.

Why do You Need a Factory Audit?

- Avoid scams and ensure suppliers’ reliability

- Verify what your suppliers (factories or trading companies) are saying

- Save time and evaluate risks early

- Select the most suitable supplier for your project

- Verify your supplier’s legitimacy

- Be confident you’re choosing the most viable source

- Protect your reputation and verify your suppliers meet all applicable regulations (including labor rights)

- Save time and money by preventing problems rather than curing them

- Monitor your suppliers quality management system over time